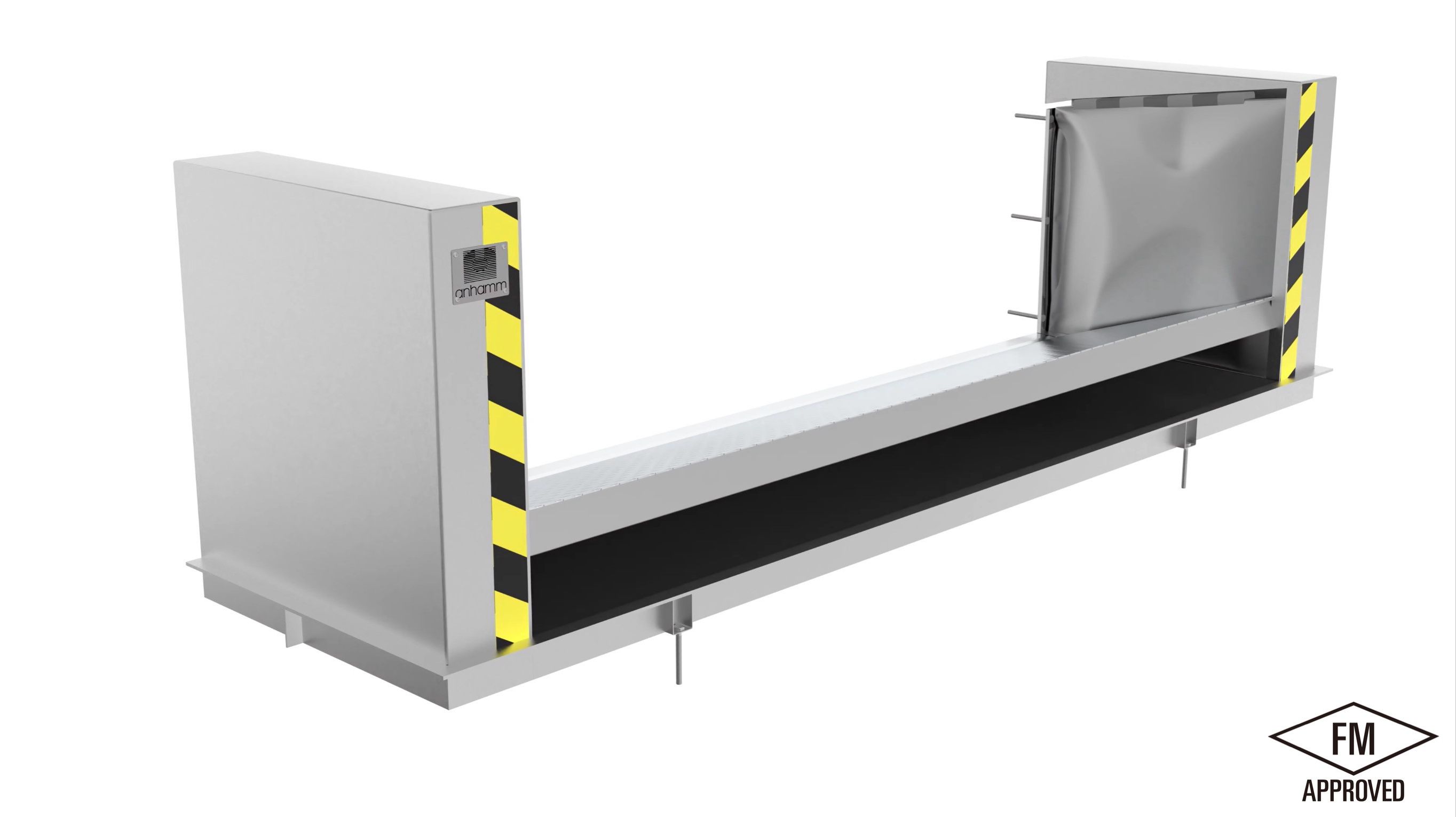

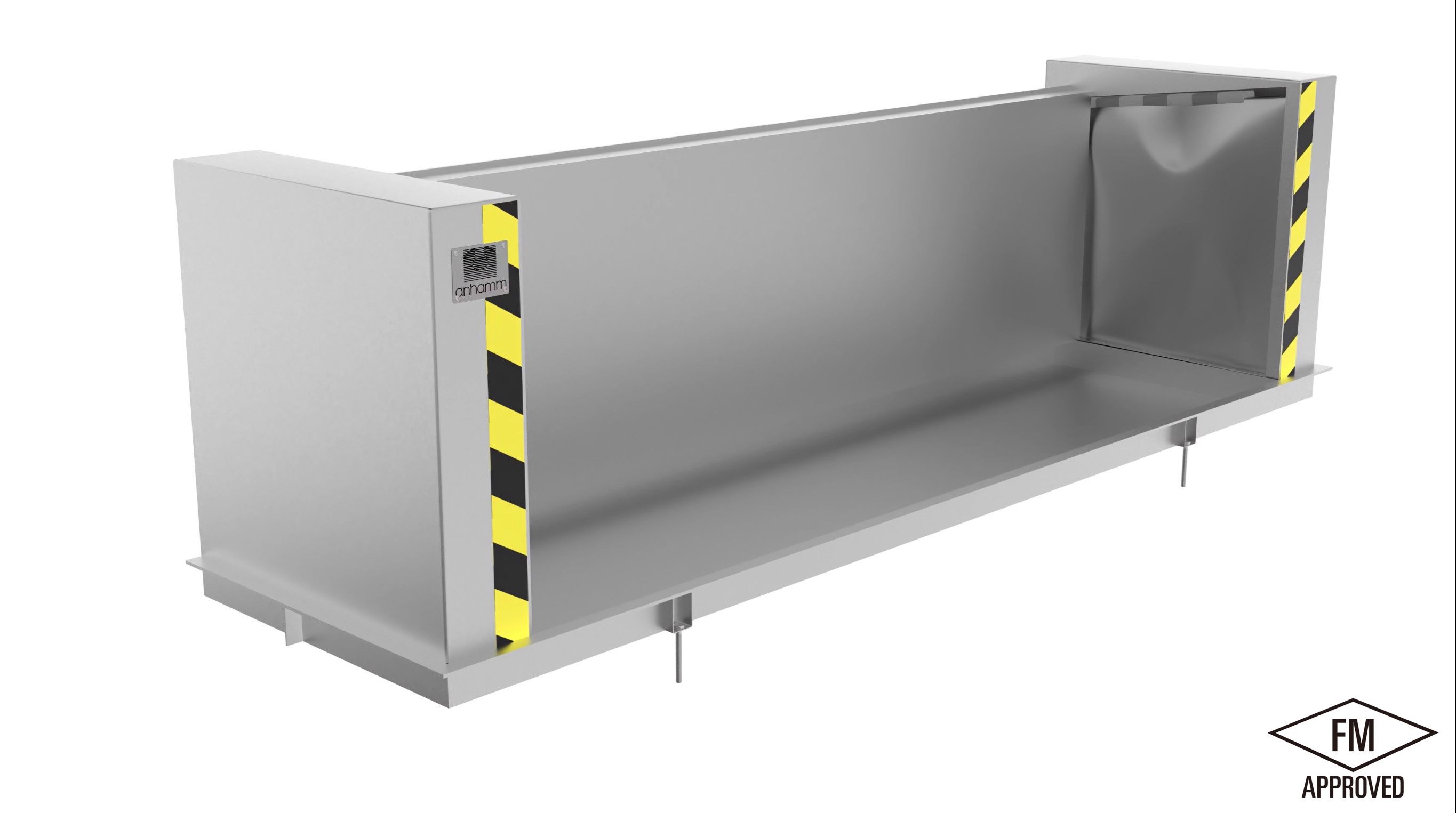

The anhamm spillbarrier

Fully automatic retention of flammable liquids and pool fire independent of external energie and electricity.

Step 1

Escaping liquid is captured across the entire opening by the barrier gates basin.

Step 2

The barrier gate is automatically raised by the escaping liquid.

Step 3

Specially-designed springs lift the barrier gate into its tightly sealed position.

Fully automatic retention of flammable liquids, trough the fm approved anhamm spillbarrier

Long-term protection of assets and the environment trough the purely automatic activation, independent on electrical power sources, ensures realiability even in the most challenging situations. The spread of flammable liquids is effectively prevented by the anhamm spillbarriers. Since 2008, the anhamm spillbarrier has set pioneering standards with heat-absorbing technology, providing reliable protection of flammable liquids 42 countries worldwide.

Liquid retention integrated into your factory traffic

Engineered for seamless integration into daily operations, anhamm spillbarriers provide discreet and noiseless passage comfort. Approved by RTW-TÜV and DMT with surpassing over 200.000 consecutive trouble-free crossings of forklifts of any kind. Within their diversity, the anhamm spillbarriers serve as silent companions and are integrated into factory routes in 42 countries, since 27 years.

Installation of the anhamm spillbarrier

The anhamm spillbarrier is supplied as a verified, integrated, and pre-configured unit. The implementation is efficient, due to minimal time effort and expertise.